After 50 years how is it possible that the same design still performs so well? And how did they manage to create a suspension system that would cope with such violent pressures?

Bill says: “It’s not a secret. I’ve told this story many times. And when I travel doing sales presentations on this I would flat-out say here’s why the cartridge performs as well as it does, yet no one’s been able to reverse-engineer it for some reason.”

Bill describes the 44-7 as an example of extreme pragmatism. Everything in it is designed to get the job done. If you actually take apart a cartridge, you’ll find the outer plastic part, which is strictly there for mounting purposes. Inside is a long, rectangular metal structure, and inside that is an insert with coils surrounded by plastic moulding. It’s very light material and very small.

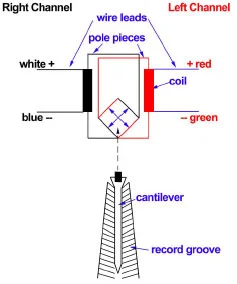

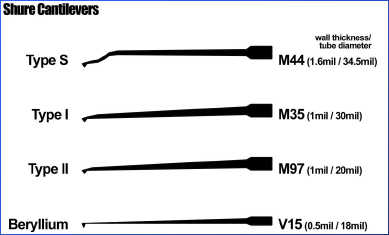

(Left) Inside a needle cartridge - the cantilever moves a magnet in between the coils, (right) different cantilever types

As the tip, or diamond, of the needle runs over the peaks and valleys in the record groove, it vibrates the s-shaped cantilever (the small aluminium tube it is attached to) much faster than the human eye can see.

This, in turn, vibrates a magnet which is attached to the other end of the cantilever, suspended by a donut-shaped synthetic bearing. The magnet moving between coils (that sit around it) creates an electrical charge which is transmitted through the terminal pins that you see sticking out the back. The more accurate the vibration, the more accurate the sound.

The material used for the bearing must have a very specific spongy quality and be cut to precise dimensions because the way this behaves and combines with the spring wire at the back is the key to the suspension system and the excellence of the 44-7. It defines the tracking force of the stylus on the record and allows the cantilever to be thin and stiff enough to produce accurate sound.

A fast 'baby' scratch (a forward and backwards motion beginning 8 seconds in) at 500 frames per second. The scratch ends with a complete stop at 34 seconds.

So by mixing and matching parts and by keeping the material as light as possible, the 44-7 maintains enough tracking force through the cantilever to provide audio accuracy while under violent forces. It’s particularly noticeable in slow-motion that, even when under severe pressure, the diamond stays rock solid in the groove while the cartridge body shakes all around it.

Bill explains: “The last place to shock-absorb anything is at the stylus level and that wobble that you’re seeing is the bearing and the spring wire, kind of resisting and holding on to make sure that the diamond stays where it is supposed to be. The s-shape also plays a role in that, but what you’re seeing is not so much that, as the bearing and spring wire letting the cantilever shake side to side.”

Back in 1964, skip resistance was a goal for the designers in order to maintain audio integrity, but they could never have conceived of someone wanting to grab the record and move it back and forth. And so it was a happy by-product that a suspension system designed primarily for an audiophile purpose worked fantastically well for turntablists.

Successfully putting all this together requires rigorous testing and it is on this that Shure prides itself. Shure even used to sell records for people to test their own audio set-up, including one to check the resonance of the record player’s tone-arm (to see how much unwanted audio it was adding) - a tonal sweep that would throw the tone-arm completely off the record.

Bill says: “The standards that Mr Shure set are followed very closely. Testing is to some ridiculous, to us it’s a matter of course. It’s what we expect and to which we all hold true."

The main checks would be for vertical compliance (the up and down movement); for frequency response - that the cartridge is representing accurately what’s on the record, and stereo separation - making sure the left and right channels remain as crisp and isolated as possible.

“So those tests are still done today because we are still manufacturing it. We still have to check the product. We archived a few hundred of these test records so we would always have something available to pull out as long as we were manufacturing the cartridge. We provided some of these test records to the Smithsonian and actually a lot of the tests that were done, over the heyday of audiophile phonograph cartridges were kind of defined by the Shure engineers as far as what should be done.”

Something that should not be underestimated is the care and expertise shown in the manufacturing process. Every cartridge is put together by hand at Shure’s own factory in Juarez, Mexico - no outsourcing. The magnet, bearing and spring wire are assembled using a microscope. The diamond is glued on by hand. The cantilevers are formed by a hand-pulled tiny lever – hand-crimped and then all put together. At the final stage, the magnet is magnetised in batches of a few dozen with a small magnetizer. The final product is tested on a machine and then packaged. Bill says some of the employees have been there for 40 years and are like family.

And for the DJs out there - how do you set up a 44-7 properly?

The key is in the overhang, according to Bill. The stylus should hang at the precise point for the particular tone arm it is attached to: “If you’re past - ahead or behind - the proper tangent point for a curved surface, you end up having the wall - because there are two walls - exerting force on that diamond. If you’re going forward, one wall will push harder in one direction than the other wall and, if you go backward, then it will flip the other way.

“So you want to make sure you’re applying pressure in the groove equally on both walls [of the groove] so that you have proper stereo imaging and don’t damage one side over the other either. If you’re at the tangent point the pressure is equal regardless of if you’re going forward or back, and that’s when wobble doesn’t happen.”